Conveyor line for plants

Roller conveyor

This section will detail the important kinds of roller conveyors present in the industry. We are highlighting the major designations here, but know that more types exist and that there is a lot of overlap between these different types. Also, these roller conveyors can be a mix of many designs, depending upon the manufacturer

Slat Chain Conveyor

Slat Chain Conveyor System offered comprise high performance and latest technology based Slat conveyors that find extensive use in production processing line requiring smooth movement of bottles, cans and other packaging.

Slat Chip Conveyor

Chip Conveyors. In the metalworking industry, tonnes of metal chips are created every day at cutting machine tools. We offer the right chip removal system and the suitable conveyor for your specific application. For disposal of chips at machine tools For transporting metal scrap and chips away from saws For disposal at stamping presses and laser cutting system

Belt Conveyor

Belt Conveyor is designed to be used in wash down areas as well as industrial environments. This is a perfect solution for slower moving assembly type applications. It is ideal to convey soft, smaller, as well as irregularly shaped products. Its high-tech design ensures smooth as well as controllable process of transporting products. It is designed with side frames using high-grade stainless steel or powder coated mild steel.

Chain conveyor system

Chain conveyor is used for transfer of components on pallets, used for light, medium and heavy loads. Chain conveyor systems are powered by continuous movement of chain arrangement. Chain conveyors are widely used in automotive industries to carry auto parts. They are available with different drive variants. Chain conveyors are ideal solution for horizontal and inclined movements. Invensys’s Chain conveyors are available with customized designs, load capacity and other specifications. We are one amongst the major industrial conveyor manufacturers in India. Our contribution to materials handling systems is very large and widely known..

Slat Chain Conveyor

Slat Chain Conveyor System offered comprise high performance and latest technology based Slat conveyors that find extensive use in production processing line requiring smooth movement of bottles, cans and other packaging.

Cleated belt conveyor

Handle various parts up an incline with an economical Titan parts conveyor. The parts conveyors can be supplied with different cleat heights and spacing to suit your application. Belt widths can be ordered from 4″ wide to 48″ wide. Standard belts are PVC, neoprene, white food handling or other optional belt types per your specifications. Floor supports are standard but portable undercarriages can also be supplied.

Wire mesh conveyor system

Wire mesh belts are used in extremely high temperatures (baking, bakery, and snack food conveying) or sub-zero temperature (frozen food conveying) applications. We provide wire mesh belt conveyors which are appropriate for the application. Closed wire mesh belts allow flexibility for conveying little components. We offer two models with a variety of wire mesh configurations. We use three different bed materials-UHMWPE plastic, roller or wears strip slider.

Air Conveyor System

air conveyor capable of lifting or lowering empty plastic bottles 90º, with or without an accumulation. This translates into an absence of speed loss on the production line, maintaining a high degree of efficiency. The compact structure helps save space and provides improved access to the rest of the factory systems.

Motorized roller conveyor

Bucket conveyor

The bucket conveyor comes in three basic types: centrifugal, continuous, and positive discharge conveyors (specialty and custom-made bucket conveyors also exist, but they will not be detailed for brevity’s sake). This section will explore each kind to show both how they differ from one another and to illustrate their most important use-cases.

Roller Conveyor

This section will detail the important kinds of roller conveyors present in the industry. We are highlighting the major designations here, but know that more types exist and that there is a lot of overlap between these different types. Also, these roller conveyors can be a mix of many designs, depending upon the manufacturer

Truck loader conveyor

Truck Loading Conveyor is excellent in quality and well tested on different quality parameters. They have been priced at very reasonable rates in the market and are available as per the demands of our customers. We have always given extra fine finishing to our final product range.

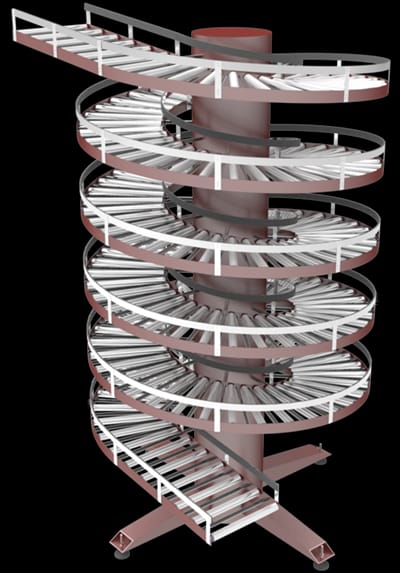

Gravity spiral conveyor

These Spiral Conveyor are best suitable for transferring cartons to ground floor. This runs on gravity and hence saves on manpower as well as power. A proper angle is selected to check the inclination and resulting velocity and hence the boxes does not get damaged.

Bucket elevator

Buckets are available in many shapes, sizes, and materials. Options differ depending on whether the unit is continuous or centrifugal. FEECO offers the following bucket styles:

Automatic Motorized spiral conveyor

Automatic Motorized spiral conveyor number of spiral trays which is manufactured using mild steel. The main body attached with vibrating motor is linked to the upper spiral tray body. As the Motor starts, the vibration sets the material in spiral upward motion. The body housing of the motor is enclosed to prevent from dusting. The Automatic Motorized spiral conveyor screen works on standard frequency of 3000 vibration per minute with max. amplitude of 1.5 mm. to 2 mm. depending on the size of the screen.

Assembly /production line

An assembly line is a production process that divides labor by breaking up the manufacture of a product into steps that are completed in a pre-defined sequence .· Large construction projects like submarines are often completed in sections, which are rolled off an assembly line

Chip Conveyor

Chip Conveyors. In the metalworking industry, tonnes of metal chips are created every day at cutting machine tools. We offer the right chip removal system and the suitable conveyor for your specific application. For disposal of chips at machine tools For transporting metal scrap and chips away from saws For disposal at stamping presses and laser cutting system

Overhead conveyor

Overhead conveyors are unique from other conveyor types in that they operate above – or over – the head of both workers and other equipment. They maximize conveyance by utilizing unused overhead space, and do so via a revolving, endless loop of chain within a rigid track, or a straight run of trollies.

SS Slat Chain Conveyors

We are the leading and prominent Manufacturer and Exporter of SS Slat Chain Conveyors.

.

Conveyor band

This type of conveyor uses a curved frame to carry items around corners, make tight transfers, or maximize available floor space. These belts’ curves can go up to 180°. True curved conveyors that do not have any straight runs can only use flat belts, as modular plastic belts require straight runs before and after curves.